Angle Lines

Quickly Punch, Drill And Shear Flats And Angles with Heavy-Duty Angle Lines

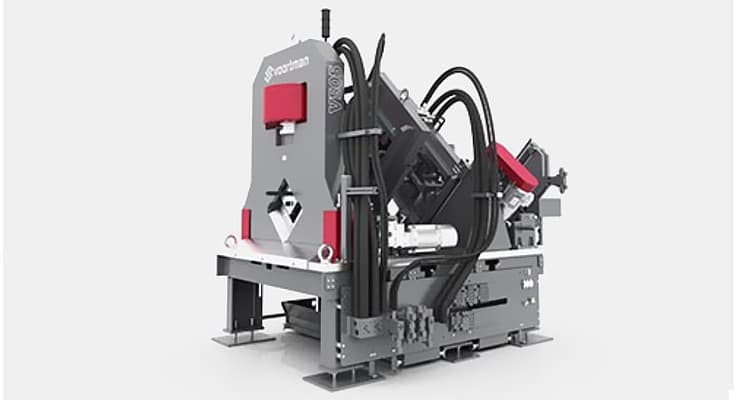

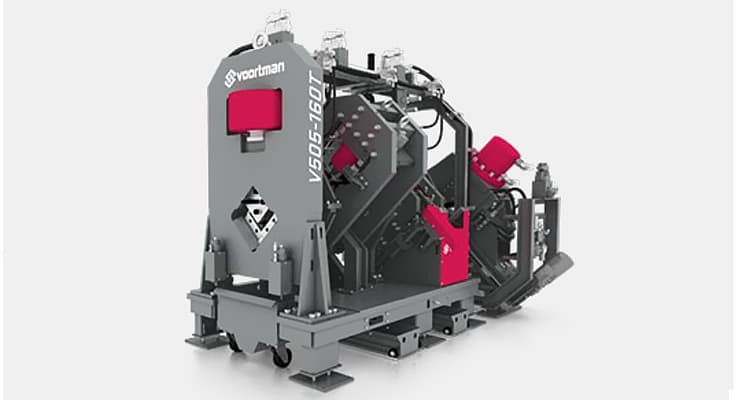

Angle Line Machines offered by Gulf States Saw & Machine Co. is the ultimate choice for your metal fabrication. It is built top speed and reliability to deliver maximum productivity and quality when you process angle bars.

Angle line machines have automatic features and impressive processing speed significantly that can enhance your workshop/industry output. With their firm/sturdy design, our angle line machines improve material capacity by processing it with minimum scrap for great results. So, if you are looking at getting the best angle line machine, GSS is your best option.

Structural fabrication requires the operation of angle lines. It is widely used to create sections of angles, and bar stocks are used as clips, angles, long bracing angles, gusset plates, and other structural segments.

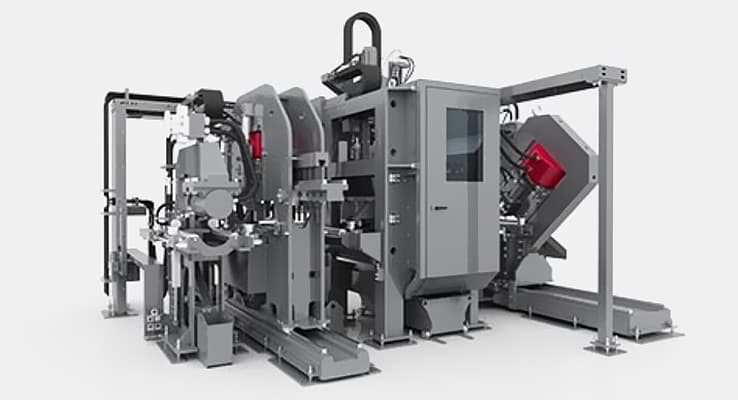

Angle processing is necessary for a structural fabrication workshop since many clips are needed throughout the metal assembly process. Angle line machines are suitable for punching, drilling, shearing, mitering, notching, and marking pieces or angles or flat bars.

The main objective of this machine is to drill holes and slots, shearing at a specific length, and even imprinting part numbers, labeling, or other distinguished markings, to support the minimum component manufacturing required in structural fabrication.

Our angle line machines provides easy and fast operations as they are engineered with top speed paired with the capacity to process various features. They are great for retaining high precision of different parts than manual processes.

FEATURES

- Capable of punching, shearing, and notching.

- It is built with a gripper feed system.

- Its automaton allows the material to efficiently process diverse shapes by moving from stick to length to completed parts, all in a single operation.

- It automates materials control, drilling holes, notches, part marking, and cutting the completed piece to length.

- Capable of processing a fabricator’s light and heavy-duty angle stock.

- Enables constant loading, punching, shearing for angle, and flat stock in a single operation.

- Produces an accuracy of about 0.30 inches.

- They are designed to maximize material efficiency by reducing scraps alongside producing top-quality processing results.

- Capable of numbering to ease your operators’ stress of noting down numbers and codes manually since the machine can retain total information through blasting, galvanizing, and painting methods.

- Designed with tool holders and various punches and dies, which boost the flexibility and hole quality while minimizing interruption caused by tool changes.

- It is operated with a single-cut shear press to cut to length angle and flat bars.

- It saves time and enables easy operation while delivering maximum productivity.

- Suitable for heavy-duty angle processing.

- Capable of supplying new length from cross-transports to the roller conveyors.

- It can handle shaped holes like squares, rectangles, circulars, and gaps.

STRUCTURAL FABRICATION MACHINERY LINKS

We Are the Structural Fabrication Machine Experts. Contact us at 877-724-7297

GSS offers a wide array of structural fabricating machines, such as Voortman Angle Lines, suitable for manufacturing processing in most industries. We’ll help you select ideal machines for your distinct operations, and you can trust our recommendations. We are more than happy to assist with your technical needs.

Contact us at 877-724-7297, or fill out our web form below.