Voortman Fabricator Automated Welding System

Automated Fitting And Full-Welding Machine For The Steel Fabricating Industry

CALL FOR QUOTE OR DETAILS – 877-724-7297

YOUR SOLUTION TO THE SHORTAGE OF QUALIFIED WELDERS

The construction industry is witnessing rapidly changing market requirements, causing several increasing challenges for structural steel fabricators. The most frequently heard challenge is the pressing need to deliver projects on schedule in combination with consistently decreasing availability of skilled fitters and welders.

This is where The Voortman Fabricator comes in, a groundbreaking automatic welding system for structural steel.

Introducing the Voortman Fabricator

The Fabricator is the premier welding system for structural steel, whose flexibility lets you choose on-the-fly between Fit & Weld or only Fit. We offer the quickest turnarounds, maximum efficiency in space utilization and choice-based flexibility – that’s what makes our ROI the fastest on the market.

- Ensure on-schedule project with reliable and flexible welding capacity

- Access a flexible workhorse free from staffing constraints

- Achieve consistent, high-quality welds, beat material tolerances

- Secure the quickest return on investment in the market

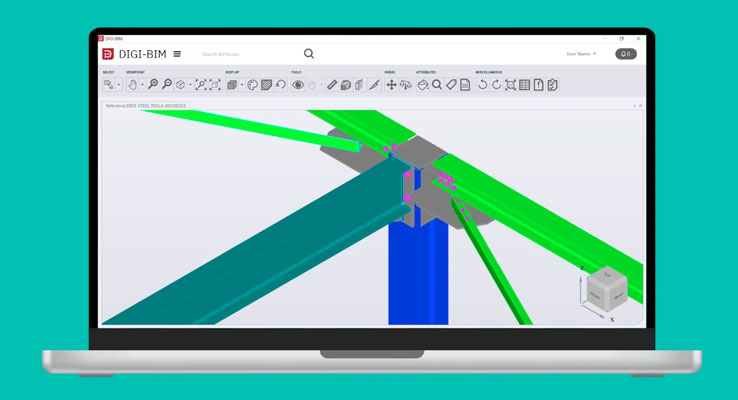

SIMPLIFY YOUR PRODUCTION TASKS WITH DIGI-WELD

With their easy setup process, our automatic welding robots really stand out from the crowd. But also our focus on work preparation is critical, as the success of your machine and its ROI are both highly dependent on thorough detailing and preparation.

The Convenience Of Digi-Weld

For decades, the structural steel industry has already relied on 3D Steel Engineering systems for a designing even the most complex structures. However, this technology was till recently still focused on generating 2D workshop drawings from a model. It wasn’t designed with robotic welding in mind – meaning that retrieving digital weld data from engineering models is not a very straightforward task. To bridge the gap between manual and automated processing this data, we use DIGI-WELD: an innovative fully cloud based tool which unlocks the potential of fully automatic welding while maintaining accuracy and quality assurance standards.

DIGI-WELD is a must for The Fabricator, providing automated weld checks & fixes to simplify the complex decision-making and assessment process of welding projects.

Seamless and Efficient Automated Welding System

COMPACT DESIGN AND SMALL FOOTPRINT

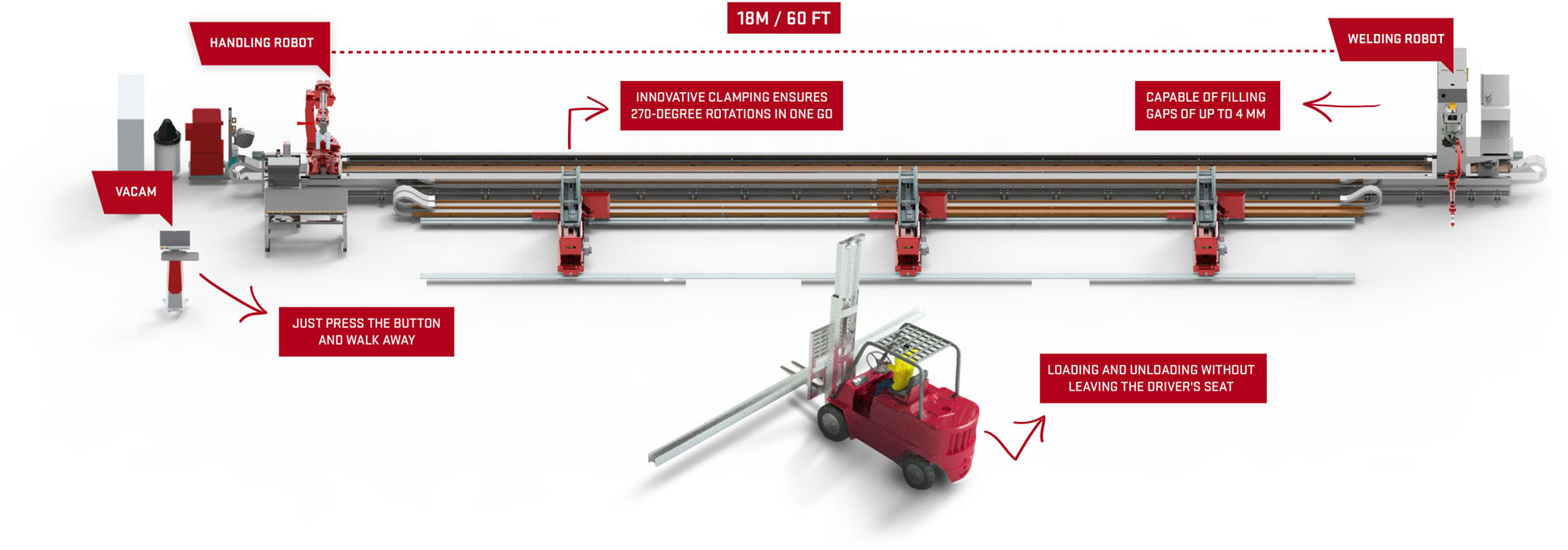

Meet the ultimate solution for structural steel fabricators looking to optimize their workspace and streamline their production processes. With its tracks conveniently positioned on one side, loading and unloading are simple to complete. The Fabricator is a space-saving system that fits easily, even in smaller workshops, thanks to its compact design and small footprint.

PROFILE LENGTHS UP TO 60 FT. (18M)

Welding lengths of up to 18m (60 ft.) make it the ideal choice for handling large-scale welding projects. To ensure even more precision and flexibility, the tracks are exceeding the maximum welding length. This enables the robots to select an optimal track position for welding, while also avoiding singular positions. With this advanced feature, the Fabricator provides maximum efficiency and output, allowing for faster completion of projects while maintaining high-quality standards.

EASY TO OPERATE IN ANY ENVIRONMENT

You can load with a forklift, side loader, or overhead crane, making it easy to operate in any workshop. Choose the method that works best for your specific layout and needs.

FAST ROTATIONS FOR MOST EFFICIENT FLOW

Designed to deliver efficient and reliable welding, makes this the ideal system for large assemblies with multiple components. Robust main beam rotation allows for quick movement between weld positions, ensuring a maximum number of parts are attached in less time – making this the most cost-effective choice.

Voortman Fabricator Components & Features

- Industrial, 6-axis Panasonic arc welding robot

- Single ‘One Side’ Robot track type

- Build-in 450A welding power source type SP-Mag / Hyper Dip

- Water cooled welding torch with quick disconnect system

- Compressor cooling with temperature control

- Mechanical torch cleaning unit

- Wire Wizard package

- Rotational positioners with hydraulic clamping. Payload up to 6.000 kg / 13.227 lbs. for 3 rotators

- Track for (motor driven) positioners for optimal positioning and grounding

- Automatic machine calibration

- Automatic Tool Center Point calibration

- Part table for positioning parts to be picked up by the handling robot

- Complete safety according to UL /RIA

- Autonomous weld path generation from 3-D engineering model till production

- DIGI-WELD work preparation software

Voortman Fabricator Specifications

Profile types main section – H, I, U & Rectangular Tubes

- Max. beam height – 23 5/8″

- Min. beam height – 3 5/32″

- Max. beam width – 15 3/4″

- Min. beam width – 3 5/32″

- Max. profile length – 60′

- Min. profile length – 9′ 10 1/8″

- Max. assembly weight – 13.227 lbs.

Secondary parts – Plates, Angle (L), RHS/SHS, T, I/H, U, Welded T’s

- Max. payload handling robot – 441 lbs.

- Wire Wizard package

- Max. welding gap – 1/8″

- Height gantry – 11′

We are Voortman Fabricator Specialists! – 877-724-7297

Contact us today for a quote or to learn more about the industry’s leading automated welding system.

Contact us at 877-724-7297, or fill out our web form below.